Polymethylmethacrylat – Wikipedia

Polymethylmethacrylat (Short sign PMMA , also Acrylic glass ) is a transparent thermoplastic plastic.

Acrylic glass was developed in 1928 in Germany, Great Britain and Spain. In Germany, the chemist Walter Bauer (1893–1968) was involved. The first cast disks made of acrylic glass were produced by Otto Röhm in Germany in 1933 and brought to market maturity. The first plastic contact lenses were made by Heinrich Wöhlk from PMMA in 1940 and used in self -experiment – up to this point there were only lenses made of sanded silicate glass, which had a significantly poorer comfort. [9] One of the first everyday products from PMMA were lids of the radio panel player combinations Braun SK 4 from 1956.

Polymethyl methacrylate is now used in large quantities for a wide range of applications (see below).

PMMA is routinely radically radically through substance, emulsion [3] , or suspension polymerization [ten] manufactured. PMMA produced in such a way is atactic and completely amorphous. Anionic polymerization (including methods of living polymerization) from PMMA is also possible.

Synthization through radical polymerization

The following reactions take place, for example, with dibe zoylperoxide as the initiator:

1. Radical education

Since organic peroxides disintegrate homolytically with low heat supply, they are well suited as a radical artist. First of all, dibe zoylperoxide is split before the resulting radical carbon dioxide (CO 2 ) separated:

2. Chain start

Now the resulting radically reacts to a new, larger, radical with methacrylic acid semester (MMA).

3. Chain growth

In chain growth, the radically reacted again with the methacrylic acid semester reacted. This reaction happens again and again, so that there is an ever larger radical.

4. Chain termination

The chain growth can break off to different ways: two growing chains can meet and combine or disproportionate or a growing chain can react with starter radical. The first option is shown here:

Pressure, temperature curve and duration of the polymerization process affect the average length of the resulting polykettes as well as the networking and interruption of the polymer chains. This in turn has direct effects on some physical and chemical properties, which, depending on the production process, can easily differ from the values mentioned below.

PMMA transmits visible light better than mineral glass. At a thickness of 3 mm, PMMA lets up to 92% of the visible light through and reflects about 4% of each of its surfaces due to its refractive index (1,4905 at 589.3 Nm). [11] It absorbs ultraviolet radiation in wavelengths below around 300 Nm (similar to ordinary window glass). Some manufacturers add PMMA coatings or additives to improve absorption in the range of 300 to 400 Nm. There are also special UV-permeable variants for use in X-ray lithography or for solaries.

PMMA allows infrared radiation of up to 2800 Nm and blocks IR from longer wavelengths up to 25,000 nm. Colored PMMA varieties make certain IR wavelengths pass, while visible light is blocked (e.g. for remote control or heat sensor applications). [twelfth]

It burns crackling, with a yellowish flame, sweet smell, dripping and without residues. When tapping with the fingernail, PMMA does not sound tinny compared to transparent polystyrene due to lower hardness.

PMMA is plastic beyond 100 ° C and this deformation is thermally reversible. It enables good chipping machining, can be very well with CO 2 -Cut or engrave lasers and is more sensitive to scratch than other thermoplastics. Connections through gluing or welding are possible.

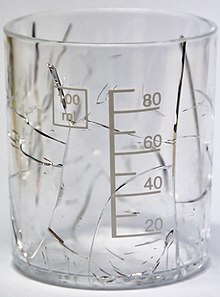

It is easy to color, weather and aging resistant, resistant to acids, clever medium concentration, gasoline and oil. However, PMMA attacks ethanol, acetone and benzene. Therefore, acrylic glass surfaces may not be cleaned with alcohol or solvents, otherwise voltage crack corrosion will arise. The good weather stability of the methacrylate polymers is due to the purely aliphatic structure and the steric shielding of the polymer chain.

If further monomers (alkyl or aryl methacrylates) are used in polymerization, it is possible to adapt the properties of the mixed polymerizer to the product requirements. For example, by suitable choice of the alcohol resort of the monomeric ester, the heat-shaped resistance or glass transition temperature can be influenced, for example: long-chain esters such as lauryl and stearyl methacrylates already show wax-like polymer properties; Esters with a strongly branched alcohol remnant deliver polymers with reduced solution viscosity. If multifunctional acrylates, such as ethylene glycoldimethacrylate, are used in the copolymerization, PMMA-Copolymers are obtained from crossing, which have modified properties and e.g. B. significantly differentiate between bending strength, the elasticity module or the abrasion resistance and can thus be adapted to the respective usage purposes.

Copolymer combinations of anionic and cationic PMMA result in interpolyel electrolyte complexes (IPEC). [13] They are preferred to coat pegs and release them in a well -given manner.

The possibilities of shaping are also very diverse. It can not only be used as a glass replacement for windows, but also for household items, such as bowls.

Technical properties of PMMA:

A large number of transparent and non-transparent objects, goods, components, semi-products or semi-finished products are made from polymethyl methacrylate in various areas. PMMA is z. B. indispensable in dentistry, where it is used for prostheses. For this purpose, the plastic with various inorganic and organic pigments, such as. B. Titidioxide, different iron oxides or AZO pigments colored so that the typical pink color is created. It is used for association rails in a transparent form. The plastic is mixed freely and hardens under heat and pressure. Activators can also be added that enable polymerization without external pressure and temperature increase.

Overview of important areas of application:

- Industry and craft

- Automotive industry: In turn signal and taillight glasses, reflectors, light ladder, door/column cladding in the exterior area (cladding of A-/B/C-pillars)

- Building: Polymer concrete, industrial floors, glazing (e.g. double blocks), for the sealing and coating of balconies and terraces, detail seals in the flat roof, industrial gym glazing (Plustherm system glazing), sanitary and furnishing components e.g. B. for bathtubs, furniture, room divider, door fillings, lampshades, etc.

- Halver ladder industry: Use as a resist (photo paint) or part of it in photo and electron beam lithography for the production of circuits and circuit boards

- Lighting technology and optics: Floodlight signs and “acrylic light design”, light covers, illuminated advertising, show glass, lentils, fresnel lenses, light wave conductors

- Aircraft construction: Disks, hoods, headlight covers

- Machine protection: Protective hoods and protective doors

- Model and prototype construction: As a mineral glass replacement for individual pieces and small series

- Pyrotechnics: Part of delay rates

- Shipbuilding: Submarine printing body, See also → Deep Rover DR1002

- Textile industry: Part of copolymer fibers (polyacrylic), See also → Polyacrylnitril

- Watch industry: Uhrglas

- Other products or areas of application

- Material for laser cutters

- Plates made of extruded acrylic are better suited for cutting, plates made of cast acrylic.

Polymethyl methacrylate (PMMA) under the trade name became known Plexiglas , registered in 1933 by Otto Röhm. [16] In Europe and Asia, Plexiglas is a registered brand name of Röhm GmbH, [17] in the USA of the Altuglas International (Arkema Group). [18] However, Röhm also sells under the name Acrylite® His acrylic glass in the USA.

In Europe, the Altuglas International Group PMMA markets under the name Altuglas ; The Arkema Group PMMA under the name Oroglas . [19]

Polymethyl methacrylate is also colloquially called acrylic glass or O-glass. O-GLAS was the brand name of the material in the GDR (for “organic glass”). The only manufacturers were the nitrogen plants Piesteritz. The trade name is guided by “Piesteritz” Piacryl ab.

There are a variety of other manufacturer -specific trade names, including Biacryl , Conacryl , Thaft , deacon , Friacryl , Hesaglas , Hesalit , Hesalite glass , Limacryl , PerClax and Vitroflex .

The recycling code for polymethyl methacrylat is 07.

Other plastics for transparent applications:

- Kai Buchholz, Ralf Beil (ed.): Plexiglas®. Material in architecture and design (On the occasion of the exhibition Plexiglass, material in architecture and design. Institut Mathildenhöhe Darmstadt, Museum Artist colony, September 16, 2007 – January 6, 2008. Translated by RAG Service, Language Service). Wienand, Cologne 2007, ISBN 978-3-87909-925-2.

- ↑ Entry to POLYMETHYL METHACRYLATE in the Cosing database of the EU Commission, accessed November 13, 2021.

- ↑ Wolfgang Kaiser, Plastic chemistry for engineers , 3rd edition, Carl Hanser, Munich, 2011, pp. 353f.

- ↑ a b c Wolfgang Kaiser: Plastic chemistry for engineers , 3rd edition, Carl Hanser, Munich, 2011, 339ff.

- ↑ a b PMMA XT. Acrylic glass extruded. (PDF; 32 kB) In: Technical data sheet. Amsler & Frey AG (Schinznach-Dorf), 1. August 2016, S. 1 , accessed on April 5, 2018 .

- ↑ a b c Properties of plexiglass. GS / XT. In: Plexiglas.de. Evonik, accessed on April 5, 2018 .

- ↑ How big is the heat expansion in acrylic? With online calculation. In: PMMA.DK. InduFlex (Stvring, Denmark), accessed on April 5, 2018 .

- ↑ Alexander Unger: Term: heat expansion coefficient. Data from the book A. Unger: Floor atlas 2011. In: fussbodenatlas.de. Unger, accessed on April 5, 2018 .

- ↑ This substance has either not yet been classified in terms of its danger or a reliable and quoted source of this has not yet been found.

- ↑ Company – history. Wöhlk Contactlinsen GmbH, accessed on March 26, 2018 .

- ↑ Rauch Puntigam, Theodor Volker: Acrylic and methacryl compounds . In: Springer Verlag Berlin (ed.): Chemistry, physics and technology of plastics in individual representations . Band 9 . Springs Publishing, 1967, ISBN 978-3642-46058-6, S. 208 ff .

- ↑ Refractive index (PMMA, acrylic glass, English) . Refractivdeindex.info of October 27, 2014.

- ↑ Altuglas International Plexiglas UF-3 UF-4 and UF-5 . Plexiglas.com from July 16, 2006.

- ↑ Diego Gallardo, Brigitte Skalsky, Peter Kleinbudde: Characterization of combinations between anionic-cationic poly(methyl methacrylate) copolymers. In: The pharmaceutical industry , Band 73, Nr. 10, 2011, S. 1875 – 1884.

- ↑ a b Degussa Röhm Plexiglas Product Description, Identical no. 211–1, Feb. 2003.

- ↑ Philipp Gellius; Musical instruments from plexiglas. : Signals for the musical world , Born 1938, p. 479f. (online at anno).

- ↑ History on plexiglas.de

- ↑ Entered in 2006-05 as a community brand under the number 003739505

- ↑ Altuglas International .

- ↑ Oroglas .

Recent Comments